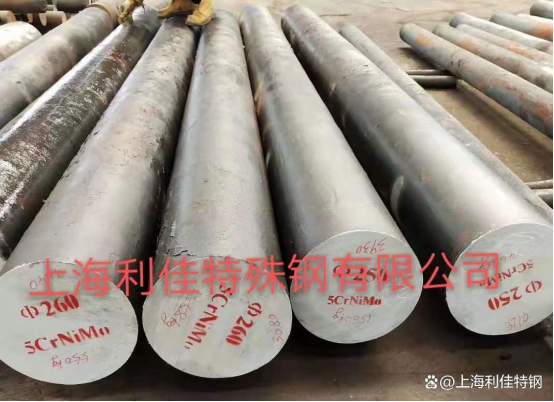

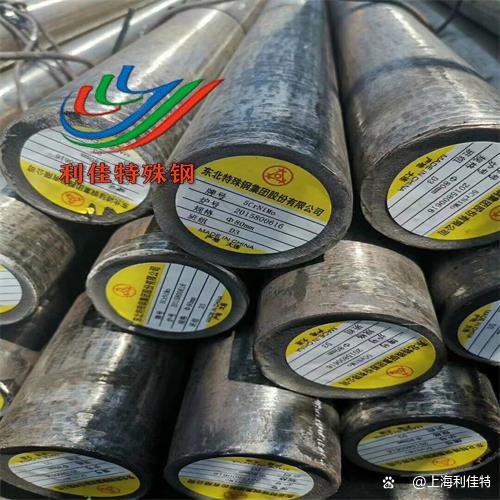

5CrNiMo mold steel: in-depth analysis of performance, application, and heat treatment process.

5CrNiMo mold steel: in-depth analysis of performance, application, and heat treatment process.

In the field of mold manufacturing, material selection is crucial, as it directly affects the service life, processing accuracy, and product forming quality of the mold. 5CrNiMo, as a high-performance hot work die steel, is widely used in the manufacturing of various hot forging dies, hot extrusion dies, and die-casting dies due to its excellent heat resistance, wear resistance, thermal fatigue resistance, and good toughness. This article will delve into the performance characteristics, application areas, and heat treatment processes of 5CrNiMo mold steel, in order to provide reference for professionals in the mold manufacturing industry.

1、 Performance characteristics of 5CrNiMo mold steel

1)The main chemical components of 5CrNiMo die steel include carbon (C), chromium (Cr), nickel (Ni), molybdenum (Mo), and other elements. Among them, carbon element enhances the hardness and strength of steel; Chromium enhances the corrosion resistance and heat resistance of steel; Nickel element helps improve the toughness and thermal fatigue resistance of steel; Molybdenum further enhances the heat resistance and red hardness of steel. The reasonable ratio of these elements enables the formation of uniformly distributed carbide particles in the microstructure of 5CrNiMo mold steel, thereby ensuring its excellent comprehensive performance.

2) Heat resistance and wear resistance

5CrNiMo mold steel can maintain good hardness and wear resistance at high temperatures, which allows it to work for a long time in high-temperature environments without deformation or damage. This characteristic makes 5CrNiMo mold steel particularly suitable for manufacturing molds that require high temperature and high pressure, such as hot forging dies and hot extrusion dies.

3) Thermal fatigue resistance:

During the use of hot work molds, the molds undergo repeated heating and cooling processes, which can easily cause thermal stress inside the molds, leading to thermal fatigue cracks. 5CrNiMo mold steel has high thermal fatigue resistance and can maintain good stability and lifespan under such harsh working conditions.

4) Good toughness is another significant feature of 5CrNiMo die steel. This makes the mold less prone to fracture when subjected to impact loads, thereby improving the safety and reliability of the mold.

2、 Application areas of 5CrNiMo mold steel:

1 )During the hot forging process, the hot forging die needs to withstand the impact force of high temperature and high pressure, while also requiring high wear resistance and thermal fatigue resistance. 5CrNiMo mold steel is one of the ideal materials to meet these requirements. It is widely used in the manufacturing of hot forging molds in industries such as automotive, aerospace, and mechanical manufacturing, such as crankshaft forging dies, connecting rod forging dies, etc.

2) Hot extrusion die

Hot extrusion is a process of extruding metal billets through molds at high temperatures. Due to the enormous pressure and friction that the mold needs to withstand during the extrusion process, it is required that the mold material has high hardness and wear resistance. 5CrNiMo mold steel has been widely used in hot extrusion mold manufacturing due to its excellent comprehensive performance, such as aluminum alloy profile extrusion molds, steel pipe extrusion molds, etc.

3)Die

casting is a process of injecting molten metal under high pressure into the mold cavity to form a shape. Due to the high temperature and high pressure of molten metal erosion that the mold needs to withstand during the die-casting process, it is required that the mold material has good heat resistance, wear resistance, and thermal fatigue resistance. 5CrNiMo mold steel also performs well in die-casting mold manufacturing, such as automotive parts die-casting molds, household appliance product die-casting molds, etc.

3、 Heat treatment process of 5CrNiMo mold steel

1 )Quenching is a key step in improving the hardness and wear resistance of 5CrNiMo mold steel. The commonly used quenching temperature is 850-900 ℃, which is rapidly cooled to room temperature after a period of insulation. During the quenching process, attention should be paid to the selection of cooling rate and cooling medium to avoid excessive thermal stress and cracks.

2)Tempering is a heat treatment process carried out to eliminate quenching stress, improve the toughness and stability of the mold. The tempering temperature of 5CrNiMo mold steel is usually between 550-650 ℃, and after a certain period of insulation, it is air-cooled or oil cooled. Tempered mold steel has high hardness and toughness, which can meet the requirements of complex working conditions.

3)In order to improve the wear resistance and corrosion resistance of 5CrNiMo mold steel, surface strengthening treatment can also be carried out, such as carburizing, nitriding, shot blasting, etc. These treatments can further improve the service life and processing accuracy of the mold.

4、When using 5CrNiMo mold steel to manufacture molds, the following maintenance measures should be noted:

1)Regular inspection: Regularly inspect the mold to promptly detect and address defects such as cracks and wear.

2) Reasonable lubrication: During the use of the mold, select lubricants reasonably to reduce friction and wear between the mold and the workpiece.

3) Temperature control: Strictly control the working temperature of the mold to avoid damage to the mold caused by excessively high or low temperatures.

4) Cleaning and maintenance: Regularly clean and maintain the mold, remove surface oil stains and impurities, and keep the mold clean and dry.

5、 Conclusion:

5CrNiMo mold steel has a wide range of application prospects in the field of mold manufacturing due to its excellent heat resistance, wear resistance, thermal fatigue resistance, and good toughness. Through reasonable heat treatment processes and scientific maintenance measures, the service life and processing accuracy of molds can be further improved. With the continuous development of mold manufacturing technology, the performance and application fields of 5CrNiMo mold steel will also continue to expand and improve. In the future, we have reason to believe that 5CrNiMo mold steel will play an important role in more fields and contribute greater strength to the development of the mold manufacturing industry. The field plays an important role and contributes greater strength to the development of the mold manufacturing industry.

Add comment