Research and development history and innovative breakthroughs of CPM3V high-speed steel

- Application of CPM 3V high-speed steel

(I) Tools

Heavy duty cutting tools

In the forestry industry, it is used to manufacture cutting tools such as logging saw blades. For example, when felling trees with larger diameters,

saw blades made of CPM 3V high-speed steel can withstand huge impact forces because the uneven material of the trees will produce sudden changes in resistance during the cutting process, and the toughness of CPM 3V high-speed steel can prevent the saw blade from chipping or breaking.

In the building and demolition industry, it is used to manufacture knives for cutting hard materials such as rebar in concrete. The rebar in concrete is hard and has a certain toughness. CPM

3V high-speed steel knives can effectively cut the rebar and maintain the integrity of the blade during the cutting process, reducing the frequency of tool replacement.

American Crucible Furnace CPM3V Powder Tool Steel CPM3V Standard CPM3V is a new steel type added to the CPM wear-resistant tool steel family.

CPM3V Chemical Composition

Carbon C:0.80

cr:7.50

V:2.75

Mo:1.30

CPM3V powder steel

CPM3V is a high toughness, high wear-resistant material, used for high wear-resistant materials with good chipping resistance and fracture resistance. CPM3V is much better than A2, D2, Cru-wear and CPMMM4 steels, close to S7, with better wear resistance and better fatigue chipping and fracture resistance.

Multifunctional tool

CPM 3V high-speed steel is widely used in outdoor adventure knives. Outdoor knives may need to perform a variety of tasks, such as cutting ropes, branches, leather, etc.

Knives made of CPM 3V high-speed steel have high hardness and can easily cut branches. The good toughness will not cause the blade to curl when cutting tough ropes, and it can also maintain a sharp edge when processing soft materials such as leather.

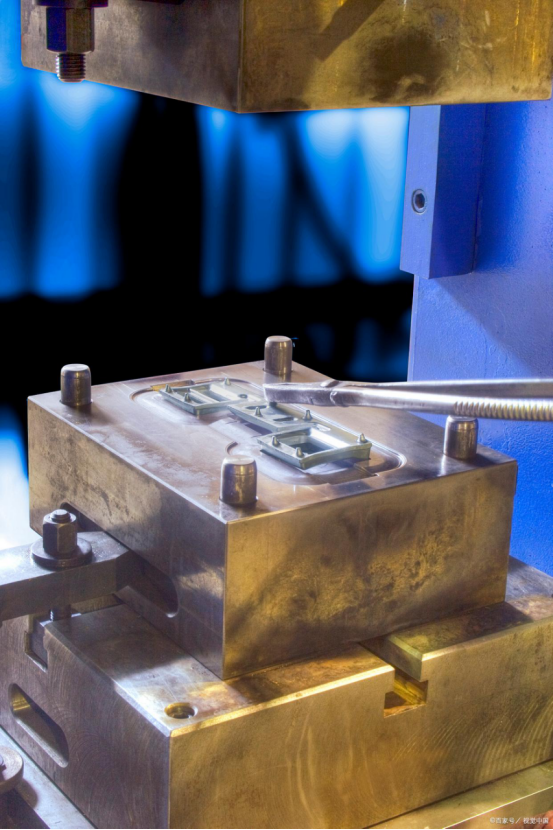

(II) Mold

Cold working die

In the manufacturing of cold stamping dies, CPM 3V high-speed steel can be used to make punches and dies. During the cold stamping process, the die needs to withstand huge impact forces.

The toughness and high hardness of CPM 3V high-speed steel can ensure that the punch and die will not be deformed or damaged under long-term stamping operations. For example, in the cold stamping production of automotive parts, such as the stamping parts for automobile bodies,

the molds made of CPM 3V high-speed steel can ensure the dimensional accuracy and quality of the stamped parts.

CPM 3V high-speed steel is also a suitable material for cold heading die manufacturing. During the cold heading process, the die has to withstand the huge pressure of the metal material during the upsetting process.

The characteristics of CPM 3V high-speed steel can make the die have a longer service life and reduce the cost of die maintenance and replacement.

2. Characteristics of CPM 3V high speed steel

(1) High toughness

The influence of microstructure

CPM

3V high-speed steel help improve its toughness. Its unique chemical composition forms a structure inside the steel that is conducive to resisting crack propagation. For example, the fine dispersed phases formed by some alloying elements can prevent the rapid propagation of cracks when the steel is impacted by external forces, just like setting up many obstacles on the road to prevent vehicles (cracks) from moving quickly.

Toughness value and actual effect

It has a high impact toughness value and is less likely to break when subjected to the same impact force than some traditional high-speed steels. In tool applications, such as the logging saw blade mentioned above, when encountering sudden resistance such as hard knots in the wood, this high toughness ensures that the saw blade continues to work normally instead of suddenly breaking. In mold applications, such as cold stamping molds may encounter some unforeseen impact forces during the stamping process,

the high toughness of CPM 3V high-speed steel can prevent damage to the mold.

(2) High hardness

The role of alloying elements

Hardness value and application

Its hardness can reach HRC58 –

60. In tool applications, this hardness is enough to cut many materials with higher hardness, such as the steel bars in the concrete mentioned above. In mold applications, it can resist the wear of the mold during use and ensure the shape accuracy of the mold. For example, in cold stamping molds, high hardness can prevent the punch and die from being scratched by the material during the stamping process, which affects the quality of the stamped parts.

(iii) Good wear resistance

Wear-resistant mechanism

Due to its high hardness and the hard phase structure formed by alloying elements, CPM

3V high-speed steel exhibits good wear resistance when in contact with other materials. In the use of cutting tools, whether cutting wood or metal, the cutting edge of the cutting tool wears slowly during long-term use. In the use of molds, such as the punch and die of cold stamping molds, during the repeated friction with metal sheets, CPM

3V high-speed steel can maintain the smoothness of the surface and reduce the dimensional deviation caused by wear.

Compared with ordinary steel

Compared with ordinary carbon steel, CPM

3V high-speed steel has significantly improved wear resistance. For example, under the same cutting or punching conditions, ordinary carbon steel tools or molds may show obvious wear in a shorter period of time, while

products made of CPM 3V high-speed steel can continue to work for a longer time, thus improving production efficiency and product quality.

Add comment